Ⅰ.Lube Oil Re-refining Plant Working Process

The working procedure of theused used lube oil re refining plant is to pump the purified transformer oil into the heater for heating, and then enter the filter for purification. Then another oil pump is used to send the filtered oil into the degassing tank for degassing and dehydration treatment, so that the water in the oil can vaporize and evaporate rapidly under the high vacuum state, and then be pumped away by the vacuum pump. The purified oil is sent to the transformer or clean oil tank through the vacuum oil drain pump and high-precision filter from the lower part of degassing tank.

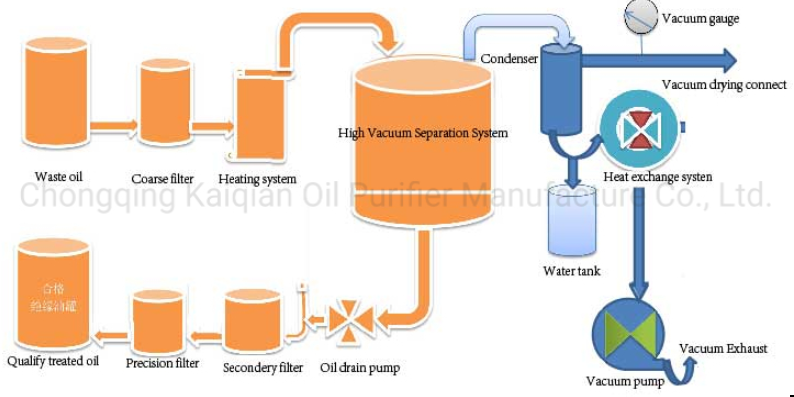

Ⅱ. Lube Oil Re-refining Plant Flow Chart

Ⅲ. Lube Oil Re-refining Plant Infrared Defoaming Technology

| Most suppliers use this technology for defoaming. In fact, their defoaming is carried out by putting air into the vacuum evaporation tank. The air contains moisture and impurities, which will cause secondary pollution to the oil |

| This is our patent technology in almost 10 years experience in transformer oil filtration. The design like bellow. |

Chinese

Chinese English

English