Application Of Vacuum Transformer Oil Purifier in Wind Power Plant

Writer: Kaiqian Oil Purifier Release time:2025-11-03 15:52 Clicks:

In wind power plants, a stable power supply depends on the normal operation of transformers. Transformer oil is the core medium of the transformer, and its quality directly affects the performance and life of the transformer. The Vacuum Transformer Oil Filter has become a key equipment to ensure the stable operation of wind power plants.

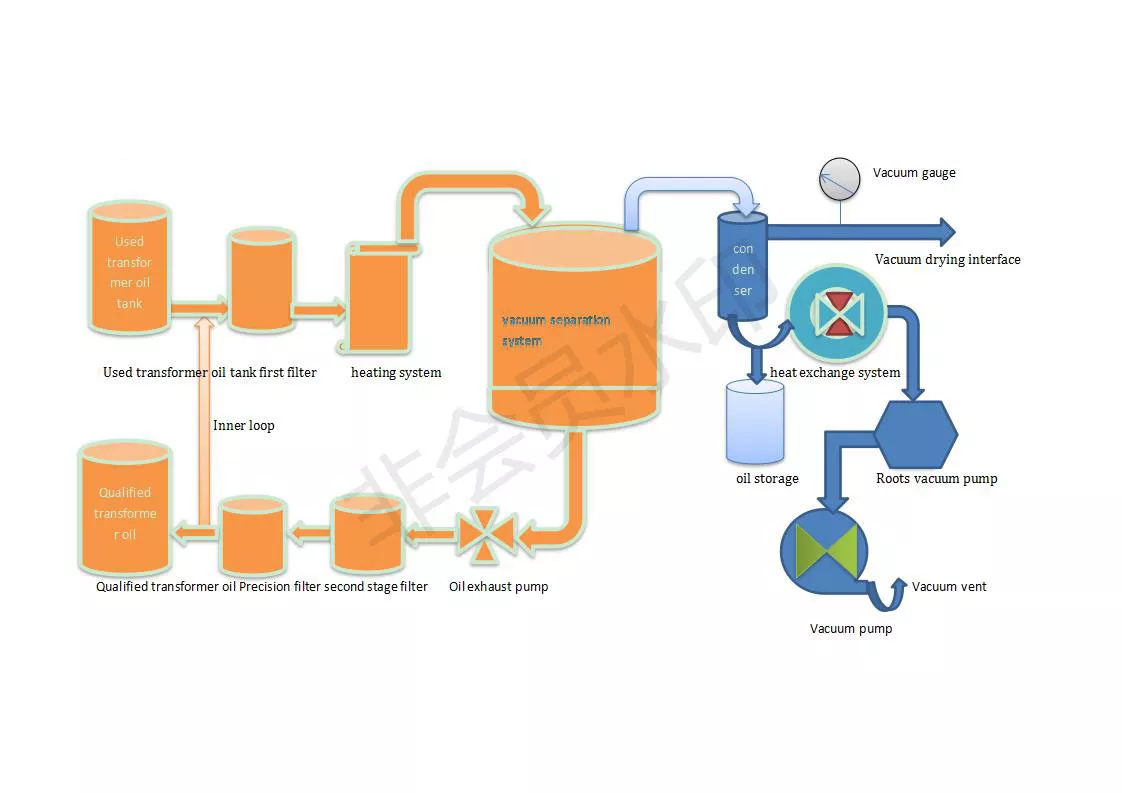

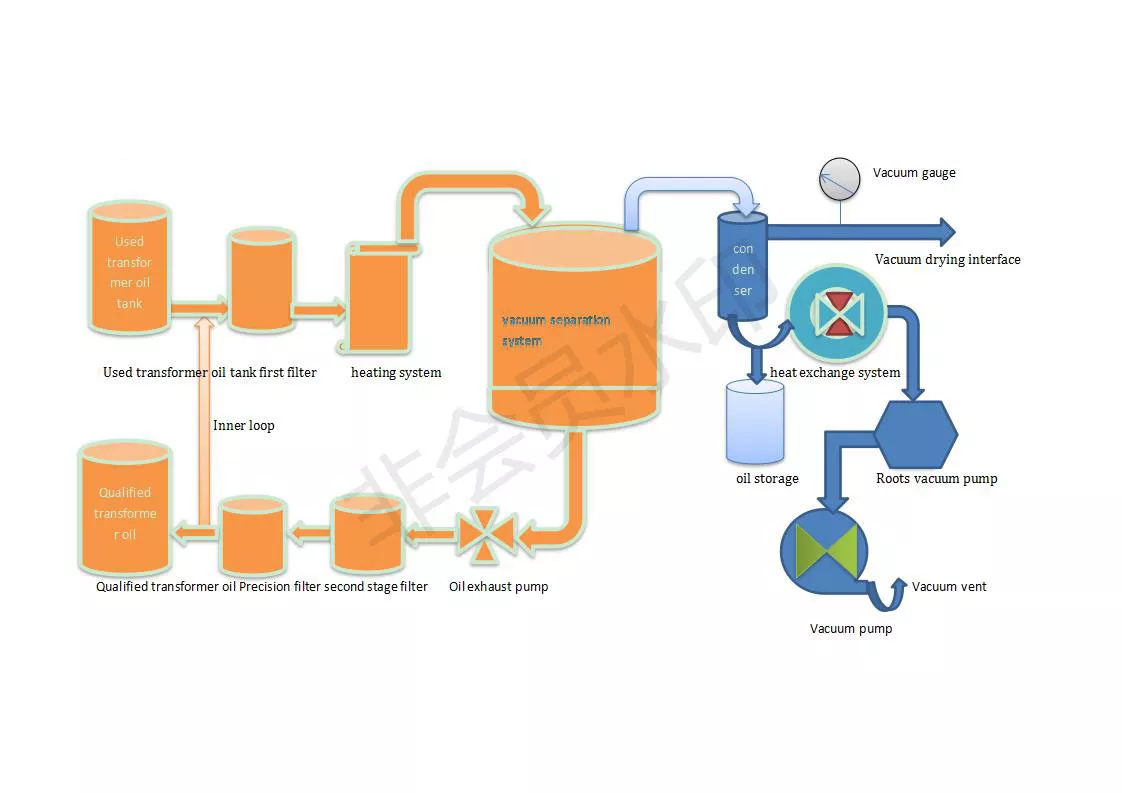

Working Principle:

The vacuum transformer oil filter is designed based on the different boiling points of water and oil. A vacuum pump first extracts air from the vacuum tank, creating a vacuum. Under atmospheric pressure, the transformer oil flows through the inlet pipe into the primary filter, which intercepts and removes larger particulate impurities. The oil then enters the heater, where it is heated to 40-75°C before entering the vacuum tank. Inside the vacuum tank, the heated oil is spun at high speed by the spray vanes, separating it into a semi-mist. At this point, the water in the oil rapidly evaporates into water vapor, which is continuously drawn into the condenser by the vacuum pump. The water vapor entering the condenser cools and returns to liquid water before being discharged. The oil drain pump then discharges the dehydrated oil in the vacuum heating tank into the fine filter, where a precision filter element removes any remaining particulate impurities. Finally, the clean transformer oil is discharged from the oil outlet, completing the entire filtration and purification process.

Role for Wind Power Plant:

-

Ensuring Stable Power Output: Wind power generation is significantly affected by natural conditions, with frequent voltage fluctuations. High-quality transformer oil ensures stable transformer operation and effectively reduces power output abnormalities caused by voltage instability. Vacuum oil purifiers remove moisture, gas, and impurities from transformer oil, improving its insulation and heat dissipation capabilities. This allows the transformer to operate stably even under complex operating conditions, effectively ensuring that wind power plants can continuously and stably supply power to the grid.

-

Extending Transformer Life: Transformers, as critical equipment in wind power plants, are expensive to purchase and maintain. Impurities and moisture in transformer oil can accelerate corrosion and wear of internal components, shortening equipment life. Regularly purifying transformer oil with a vacuum oil purifier can effectively mitigate these adverse effects, extending transformer life, reducing equipment replacement frequency, and saving wind power plants significant capital on equipment upgrades.

-

Improving Power Generation Efficiency: Transformer oil purified by a vacuum oil purifier significantly improves its heat dissipation performance. During the operation of the wind turbine, the heat generated by the transformer can be dissipated in time, avoiding the transformer's reduced capacity operation due to excessive oil temperature, ensuring that the generator always operates at rated power, thereby improving the power generation efficiency of the entire wind power plant and increasing power generation.

Transformer Insulating oil Purifier in the Gansu project

Advantages:

- Efficient Dehydration and Degassing: Utilizing a high-vacuum tank and large-scale, three-dimensional flash evaporation technology, this system significantly improves dehydration and degassing efficiency, rapidly reducing moisture and gas content in transformer oil to standard levels and ensuring the oil's insulation properties.

- Precision Filtration: Equipped with a multi-stage precision filtration system, it accurately intercepts particles larger than 0.5μm, achieving a filtration accuracy of ≤1μm, effectively ensuring transformer oil cleanliness.

- Intelligent Operation: Equipped with automated control features such as an infrared-controlled defoaming device, mechanical and electronic oil level control, and an overpressure alarm, it enables semi-automatic operation and is easy to use, reducing labor costs and the risk of operational errors.

- Flexibility and Convenience: Compact and lightweight, it is easy to move. Interchangeable oil inlets and outlets allow for flexible switching during operation via valve control without disassembling the oil pipes, adapting to the diverse operating scenarios of wind power plants. Versatile Applications: It not only filters and purifies transformer oil, but can also be used for on-site vacuum oil filling and replenishing of sealed oil-immersed equipment, as well as equipment vacuum evacuation. It can even regenerate and purify even slightly deteriorated transformer oil, bringing it up to acceptable oil standards and meeting the diverse operational and maintenance needs of wind power plants.

Power transformer insulating oil purifier trailer in the Guyuan project

With its unique operating principle, functions, and advantages, the transformer oil vacuum filter has become an indispensable component in wind power plant equipment maintenance and operational assurance. It provides solid support for the stable and efficient operation of wind power plants, contributing to the sustainable and healthy development of the wind power industry.

For more details, please contact us:

Email:oilrecycling@kaiqiancq.com

WhatsApp: +8617723167431

简体中文

简体中文

English

English

Français

Français

Русский язык

Русский язык

Polski

Polski

日本語

日本語

ภาษาไทย

ภาษาไทย

Deutsch

Deutsch

Português

Português

español

español

Italiano

Italiano

한어

한어

Tiếng Việt

Tiếng Việt

Pilipino

Pilipino

بالعربية

بالعربية

বাংলা

বাংলা

IndonesiaName

IndonesiaName

ກະຣຸນາ

ກະຣຸນາ

Türkçe

Türkçe

简体中文

简体中文

English

English

Français

Français

Русский язык

Русский язык

Polski

Polski

日本語

日本語

ภาษาไทย

ภาษาไทย

Deutsch

Deutsch

Português

Português

español

español

Italiano

Italiano

한어

한어

Tiếng Việt

Tiếng Việt

Pilipino

Pilipino

بالعربية

بالعربية

বাংলা

বাংলা

IndonesiaName

IndonesiaName

ກະຣຸນາ

ກະຣຸນາ

Türkçe

Türkçe