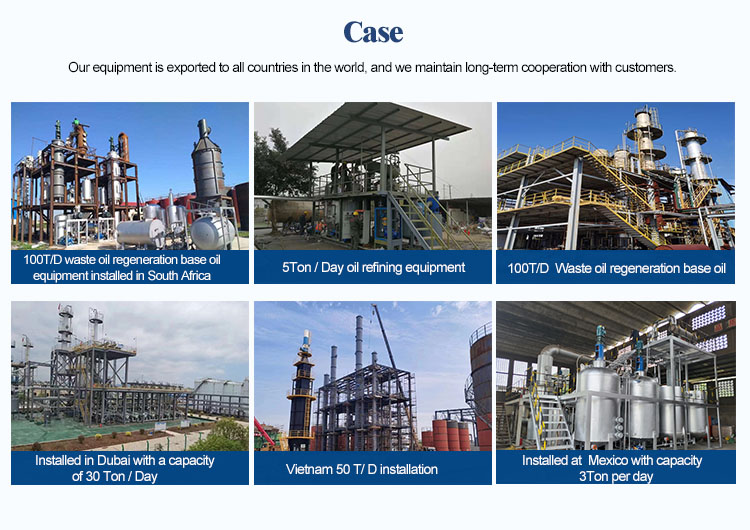

Ⅰ. Waste Oil Distillation Machine Application

The tire and plastic pyrolysis oil distillation equipment is suitable for the distillation and purification of the crude pyrolysis oil from waste plastic and used tires. The process can produce high-quality fuel oil by vacuum distillation from the cracked tire oil and plastic oil in high vacuum environment, so as to improve the market use of the pyrolysis oil.

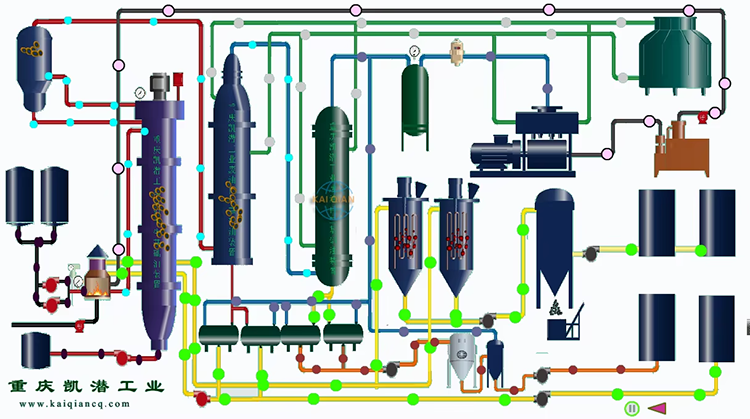

Ⅱ. Waste Oil Distillation Machine Process Principle

The distillation equipment adopts high vacuum distillation technology, atmospheric and vacuum technology to realize liquid-liquid separation by the difference of mean free path of molecular movement of different substances. The free path of molecular motion refers to the path between two adjacent collisions of a molecule. When the oil is heated, light and heavy molecules will overflow the liquid surface and enter the gas phase. Because the free path of light and heavy molecules is different, the molecules of different substances will move different distances after overflowing the liquid surface, so as to achieve the purpose of substance separation. The vacuum distillation technology not only speeds up the molecular overflow time, but also improves the oil yield.

Ⅲ. Waste Oil Distillation Machine Technical Advantages

3.1 The equipment adopts atmospheric and high vacuum separation technology, with low working temperature (far below boiling points), high vacuum degree (no-load ≤ 5pa), short heating time (in seconds), high separation efficiency, especially suitable for the separation of high boiling point, heat sensitivity and readily oxidizable substances.

3.2 It can effectively separate and remove low molecular substances (deodorization), heavy molecular substances (decolorization) and impurities in the used oil.

3.3 The equipment uses high vacuum scraping film evaporator, which has high separation rate, far higher than the traditional distiller. The common evaporator begins carbonizing and coking at 300 ℃, that is to say, the quality of recycled oil is obviously reduced, and the recovery rate is also obviously reduced. Because there are many impurities such as gum, asphalt and free carbon in the used oil, the high vacuum scraping film evaporator can effectively prevent these substances from coking, effectively guarantee the long-term operation of the equipment and improve the regeneration output of the waste oil.

3.4 The by-products such as tail oil, residual oil, light component oil and extraction oil can be sold as industrial fuel oil.

3.5 The vacuum distillation equipment investment is less, equipment construction cycle is fast, product income is high.

3.6 According to customers’ requirements, the vacuum distillation equipment can be divided into continuous-production and batch production.

Ⅳ. Waste Oil Distillation Machinet Product Yield

The product yield (calculated according to the crude oil without water content) produced by this process is as follows:

4.1 85-90% of refined products of industrial fuel oil meet the standard of non-standard diesel oil.

4.2 The equipment is highly automated and easy to learn. It only needs 1-2 workers to operate. Generally, you can learn to operate in three or four days and start the process in a week.

Ⅴ. Waste Oil Distillation Machine Refined Oil Index

NO. | Item | Test Method | Refined Oil Index | Standard Value |

01 | Viscosity(15℃) | ASTM D1298 | 0.84kg/L | .....kg/L |

02 | Viscosity index (40℃) | ASTM D445 | 3.36cst | 1.6-5.8cst |

03 | Pour Point | ASTM D97 | -19℃ | ≥0℃ |

04 | Flash Point(open) | ASTM D93 | 60℃ | ≥55 |

05 | Water Content | ASTM D95 | Trace%vol | ≤Trace %vol |

06 | Sulfur | ASTM D1226 | 0.15%Wt | 0.2%Wt |

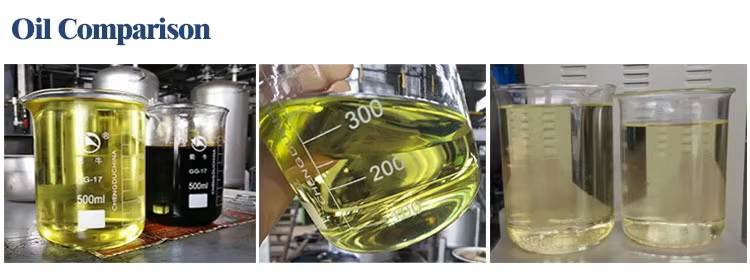

07 | color | Yellow / transparent / Pale yellow / transparent | ||

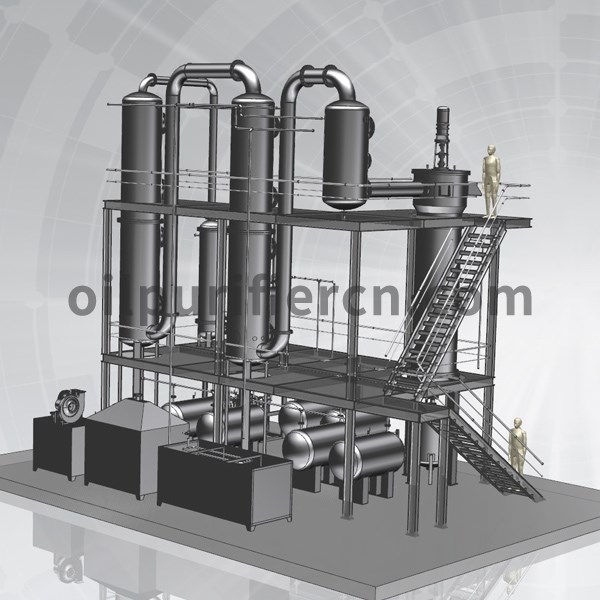

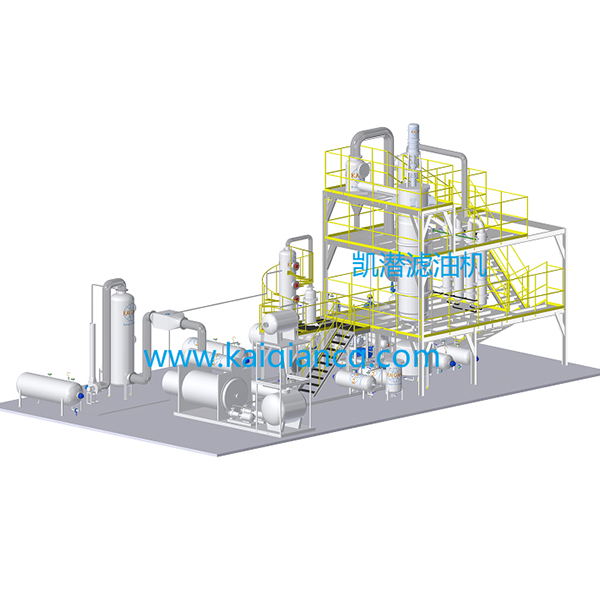

Ⅵ. Waste Oil Distillation Machine Models and Specifications

Model designation | Unit | KTS-C5 | KTS-C15 | KTS-C20 | KTS-C30 | KTS-C50 | KTS-C100 | |

Handling Capacity | T/D | 5 | 15 | 20 | 30 | 50 | 100 | |

Working Pressure | Mpa | ≤0.5 | ||||||

Working vacuum | pa | -5~ -20 | ||||||

Temperature | ℃ | ≤350 | ||||||

Working Noise | dB(A) | ≤85 | ||||||

The power | V | 380-480V/50-60Hz Three-phase four-wire(Customizable as required) | ||||||

Total Power | KW | 80 | 120 | 125 | 140 | 180 | 210 | |

Cooling Water | M³ | 35 | 40 | 50 | 60 | 80 | 160 | |

Weight | T | 16 | 19 | 22 | 26 | 46 | 56 | |

Dimension | L | m | 15 | 17 | 17 | 25 | 35 | 45 |

W | m | 4 | 6.5 | 10 | 12 | 16 | 20 | |

H | m | 6 | 6 | 6 | 6 | 6.5 | 8 | |

| Notes | 1.We can customize 150 -300TPD equipment as required 2.Diesel and natural gas heating method will be more ceonomical | |||||||