Ⅰ. Lube Oil Treatment System Working Principle

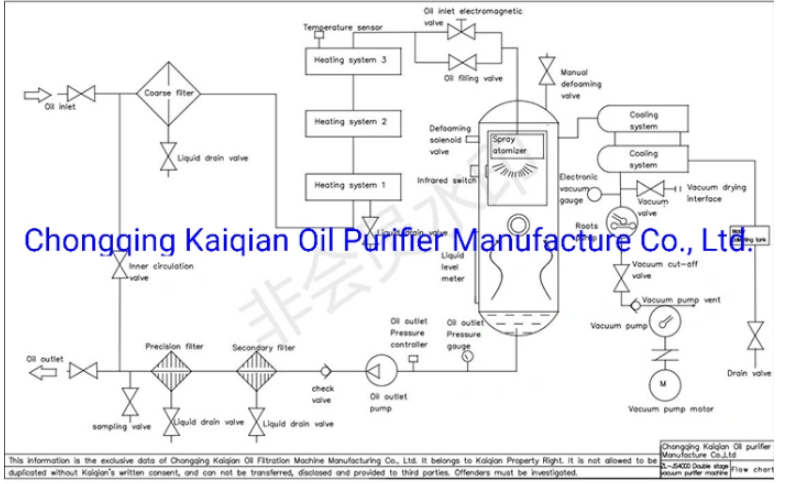

Vacuum separation of lube oil treatment system adopts advanced design vacuum separation technology. The hot oil enters the vacuum separator through the distributor into a coarse-grained mist, and the water begins to evaporate. The oil mist falls on the reaction tower and forms a parabolic operation in the tank. Through short-term circulation, purification can be achieved.

Ⅱ. Lube Oil Treatment System Working Process

Ⅲ. Lube Oil Treatment System product structure

Lube oil treatment system has the functions of automatic oil supply, constant temperature heating, automatic stop of full oil supply pump, vacuum separation, defoaming treatment, automatic oil output, interlock, alarm protection and other functions.

This system can monitor pressure, temperature and vacuum degree on line.

The human-machine interface is strong, the operation is simple, and the unmanned operation can be achieved during the whole process.

Ⅳ. Treated Oil Index by Lube Oil Filtration Machine

Item | Unit | Index | Method |

Mechanical Impurities | % | 无 None | GB/T511 |

Demulsification Value | Min | ≤15 | GB/T7605 |

Water | Mg/L | ≤50PPM | GB/T7600 |

Acid | mgkoH/g | ≤0.3 | GB/T264 |

Cleanliness | Class | ≤6 | NAS1638 |

Filter Precision | ≤5um | ||

Ⅴ.TY-R Lube Oil Filtration Machine Technical Parameters

Model Item | Unit | TY-R20 | TY-R30 | TY-R50 | TY-R80 | TY-R100 | TY-R150 | TY-R200 | TY-R300 | ||

Flow Rate | L/min | 20 | 30 | 50 | 80 | 100 | 150 | 200 | 300 | ||

Working Vacuum | Mpa | -0.08~-0.096 | |||||||||

Working Pressure | Mpa | ≤0.5 | |||||||||

Working Temp. | ℃ | ≤10~80 Adjusted freely | |||||||||

Power | V | 380-480V/50-60Hz Three-phase four-wire(Customizable as required) | |||||||||

Electrical Heating Power | KW | 24 | 30 | 36 | 42 | 54 | 66 | 72 | 90 | ||

Total Power | KW | 26 | 33 | 39 | 45 | 57 | 72 | 86 | 105 | ||

Inlet & Outlet Pipe Diameter | mm | Φ25 | Φ32 | Φ42 | Φ42 | Φ48 | Φ48 | Φ50 | Φ60 | ||

Weight | Kg | 480 | 550 | 600 | 1050 | 1150 | 1450 | 1600 | 2200 | ||

Dimension | L | mm | 1150 | 1350 | 1400 | 1500 | 1550 | 1550 | 1600 | 1650 | |

W | mm | 910 | 1000 | 1100 | 1300 | 1350 | 1350 | 1400 | 1450 | ||

H | mm | 1550 | 1600 | 1650 | 1750 | 1800 | 1850 | 1900 | 2000 | ||

Note : The size and weight of the equipment with the technology progress slightly adjusted , in order to prevail in kind.

(It can be produced as closed, the marquee and trailer type , according to customer requirements)