Ⅰ. Vacuum Transformer Oil Purifier Usage

It is widely used for oil purification and vacuum hot oil circulation drying during the installation and maintenance of various large transformer equipment. It is not only used for insulating oil purification in 110KV–550KV transformers, but also suitable for high-grade new oil and deep processing of imported oil.

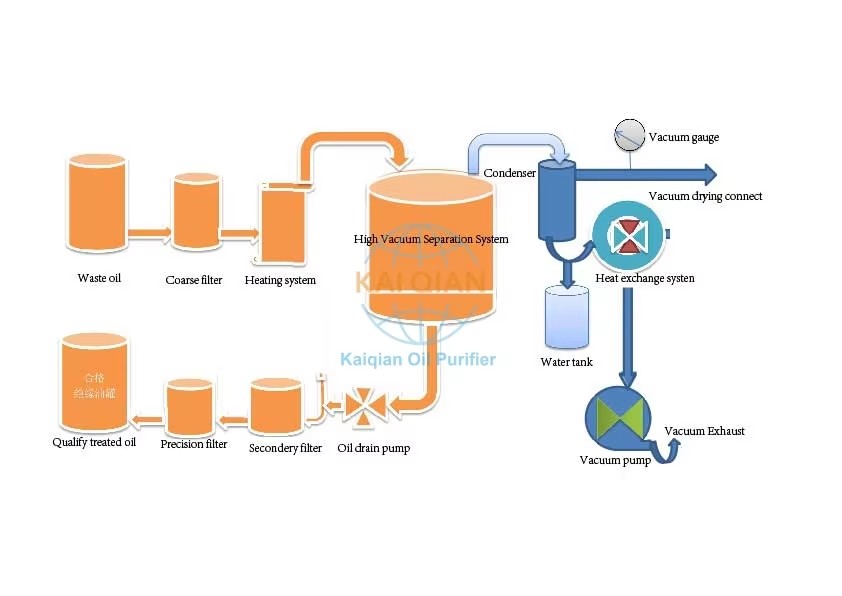

Compared with a single-stage vacuum purifier, this machine features an enhanced Roots pump pressurization system, a secondary high-vacuum separation system, and a three-dimensional flash rapid evaporation system. It can quickly dewater, degas, and remove acetylene, acid value, and free carbon.

After treatment, the breakdown voltage of the transformer oil will be significantly improved. The machine is not only used as an oil purifier but also serves as an independent vacuum source with functions for vacuum drying and oil injection for transformer equipment.

Ⅱ. Vacuum Transformer Oil Purifier Function

- Dehydrates, degasses, and removes impurities from insulation oil in main transformers ranging from 110 kV to 1100 kV.

- Effectively removes acetylene from insulation oil in 110 kV to 1100 kV main transformers.

- Performs vacuum drying of insulation oil in main transformers from 110 kV to 1100 kV.

- Capable of removing 100% of free water, 99.9% of dissolved water, 100% of free gas, and 98% of dissolved gas.

- Enhances the dielectric strength of transformer oil, improving its overall performance.

- Prevents the formation of sludge and contaminants, ensuring a longer service life for transformer oil.

- Reduces the acid value and removes free carbon to extend the lifespan of transformer equipment.

- Offers customizable features, such as PLC control, frequency conversion technology, and trailer options for mobility and ease of use.

- Capable of handling both new and used oils, offering versatility in various transformer oil treatments.

- Equipped with advanced monitoring systems for real-time performance tracking and optimization.

Ⅲ. Oil Parameters After Treatment

Items | Unit | Index | Testing method |

Mechanical impurities | % | None | GB/T511 |

Demulsification value | Min | ≤30 | GB/T7605 |

Water Content | Mg/L | ≤5PPM | GB/T7600 |

Acid value | mgkoH/g | ≤0.3 | GB/T264 |

Cleanness | Grade | 6 grade | NAS 1638 |

Breakdown voltage value | KV | 55-65 | GB、DL Or IEC Standard |

Residual gas | ≤0.01% | ≤0.01 | The gas content measurement according to the standard of GB, DL and IEC |

Acetylene | Mg/L | 0 | The gas content measurement according to the standard of GB, DL and IEC |

Filter precision | 1um | ||

Ⅳ. Vacuum Transformer Oil Purifier Technical Parameters

Model Item | Unit | ZL-JS30 | ZL-JS50 | ZL-JS100 | ZL-JS150 | ZL-JS200 | ZL-JS300 | |

Flow Rate | L/min | 30 | 50 | 100 | 150 | 200 | 300 | |

Work vacuum | Mpa | -0.08~0.098 | ||||||

Work pressure | Mpa | ≤0.5 | ||||||

Work temperature | ℃ | 45-65 Adjustable | ||||||

Power supply | V | 380-480V/50-60Hz-Three phase four wire (Customized) | ||||||

Heating power | KW | 30 | 36 | 72 | 96 | 144 | 180 | |

Total power | KW | 33 | 40 | 76 | 102 | 152 | 190 | |

Diameter of intel&outlet | mm | Φ32 | Φ38 | Φ42 | Φ48 | Φ64 | Φ76 | |

Weight | Kg | 685 | 850 | 1200 | 1650 | 2300 | 3100 | |

Dimensions | Length | mm | 1100 | 1200 | 1450 | 1700 | 1750 | 1800 |

Width | mm | 950 | 1000 | 1150 | 13500 | 1450 | 1500 | |

Height | mm | 1450 | 1500 | 1700 | 2000 | 2000 | 2100 | |

Why choose us?

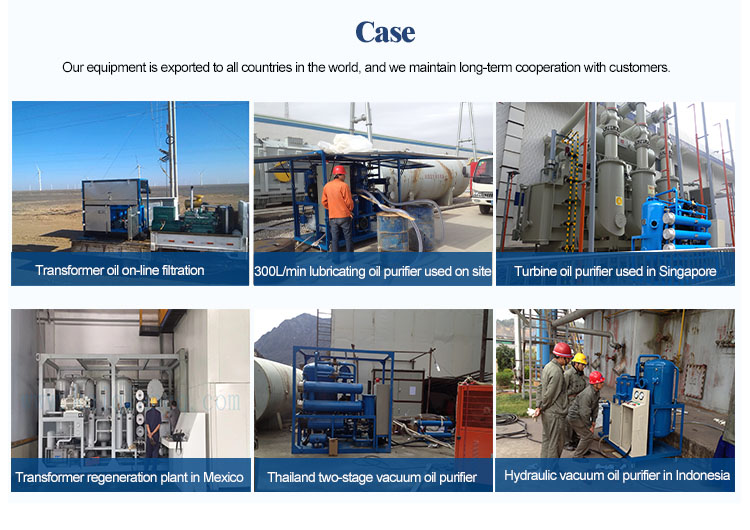

Chongqing Kaiqian Oil Purifier Manufacturer Co.,Ltd can produce 2000 sets of oil purifier equipment and other fluid purification equipment every year. We are one of the most competitive companies focusing on the research and manufacture of high-tech oil purifier. The equipment is exported to nearly fifty countries around the world! Provide online technical support and on-site service engineering to support customers' operational needs.

We provide various oil purifier models. Our product size and material are customized on demand, with a capacity ranging from less than 1200L/H to 24000L/H.

→1. We are an oil purifier manufacturer, factory direct sales, no middleman, competitive price.

→2. Our equipment with imported accessories, and the quality of the products produced is stable.

→3. On-time delivery, we can provide excellent service, transportation, documentation, etc.

→4. We will reply to your inquiry within 24 hours.

→5. With more than 18 years of R&D experience and a professional technical team in the oil purifier industry, our customers feel relaxed and happy when cooperating with us.

FAQ

1. How long does it take to deliver the equipment?

→Usually, the delivery time of the machine is about 25 working days. In case of emergency, please contact us by phone: +86 139 8303 172

2. Is product quality guaranteed?

→Strictly in accordance with 9001 quality standards, the whole machine is guaranteed for one year under normal operation.

3. What are the consumable parts of the equipment? How often do you need to replace the filter?

→Except for the filter, there are no consumable parts in the oil purifier. It can last at least 3,000 hours, but this depends on the cleanliness of the oil.

4. Can the product be customized?

→ It can be customized according to customer needs. We can customize the color, industrial power and your logo on the machine. We can also customize the oil pump, vacuum pump, flow, plc electronic control system, trailer, explosion-proof, stainless steel material, etc. according to your needs.

5. What is the material of your machine?

→ Carbon steel or stainless steel (standard model is SUS304, can be customized according to your requirements)