Ⅰ. Usage of Transformer Oil Filtration Systems

1.Filtering impurities in transformer oil

2.Enhance the performance of transformer oil in 300kv-500kv transmission project

3.Remove acetylene in oil

4.Remove acid value from oil

5.Improve the insulation effect of transformer

Maximum capacity of transformer oil filtration unit can meet the purification of insulating oil of a single transformer of 300 tons.

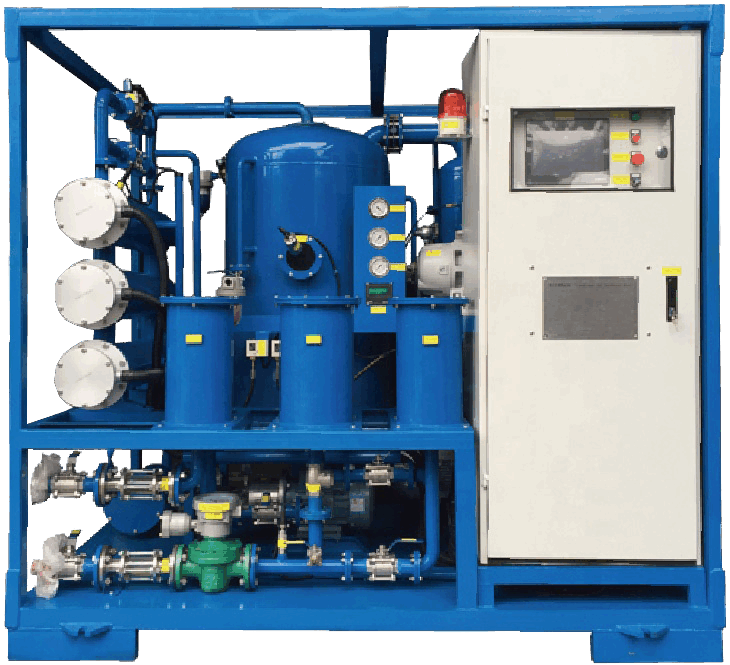

Ⅱ. Transformer Oil Filtration Systems Features:

1.High vacuum, fast oil filtration

2.For large transformer installation, maintenance in the oil treatment

3.Vacuum oil injection, circulating hot oil drying

4.On-line oil filtration

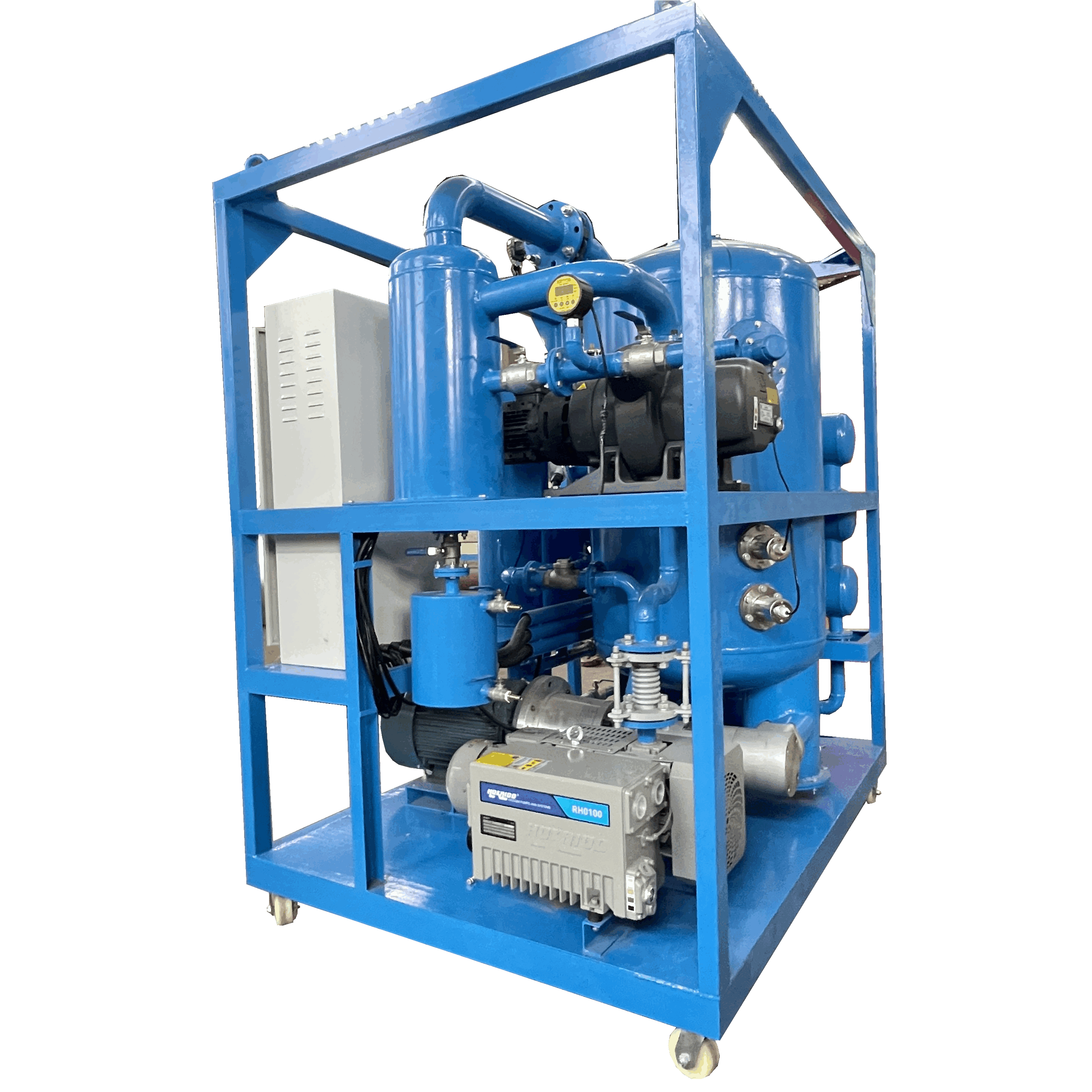

As an oil water filtration system manufacturer, KaiQian provide a large number of oil purification machine, the equipment can be selected from a full range of models, to meet the demand for any customization. Can be produced according to customer technical requirements; rainproof closed type, trailer type, the main components of the imported configuration.

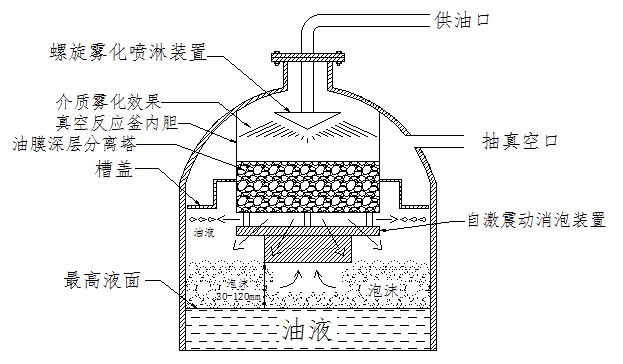

KaiQian first self-excited vibration defoaming system introduction

KaiQian transformer oil filtration unit world's first two-stage high transformer oil filtration unit self-excited vibration defoaming technology in the current high-vacuum oil filter machine defoaming technology is in the world's leading level, the self-excited vibration defoaming system by the vacuum separator kettle, self-excited vibration defoaming device, atomization device, reaction tower, separation tower, separation room, separation sieve tower, pumping chamber, the poly tank composition.

My company produces a new oil water filtration system self-stimulation vibration defoaming system, through the self-stimulation vibration to eliminate the foam in the vacuum tank, vacuum oil filter for a long time to work electronic vacuum gauge measurement value of -5 Pa-133 Pa vacuum tank no oil foam rising phenomenon can be realized man-machine separation is safe and reliable.

Ⅲ. Transformer Oil Filtration Systems Oil Parameters After Treatment

Items | Unit | Index | Testing method |

Mechanical impurities | % | 0 | GB/T511 |

Demulsification value | Min | ≤30 | GB/T7605 |

Water Content | Mg/L | ≤5PPM | GB/T7600 |

Acid value | mgkoH/g | ≤0.3 | GB/T264 |

Cleanness | level | 6 | NAS 1638 |

Breakdown voltage value | KV | 55-65 | GB、DL Or IEC Standard |

Residual gas | ≤0.01% | ≤0.01 |

The gas content measurement according to the standard of GB, DL and IEC |

Acetylene | Mg/L | 0 | The gas content measurement according to the standard of GB, DL and IEC |

Filter precision | 1um | ||

Ⅳ. Technical parameters for Transformer Oil Filtration Systems

Model Item | Unit | ZL-JS30 | ZL-JS50 | ZL-JS100 | ZL-JS150 | ZL-JS200 | ZL-JS300 | |

Flow Rate | L/min | 30 | 50 | 100 | 150 | 200 | 300 | |

Work vacuum | Mpa | -0.08~0.098 | ||||||

Work pressure | Mpa | ≤0.5 | ||||||

Work temperature | ℃ | 45-65 Adjustable | ||||||

Power supply | V | 380-480V/50-60Hz-Three phase four wire (Customized) | ||||||

Heating power | KW | 30 | 36 | 72 | 96 | 144 | 180 | |

Total power | KW | 33 | 40 | 76 | 102 | 152 | 190 | |

Diameter of intel&outlet | mm | Φ32 | Φ38 | Φ42 | Φ48 | Φ64 | Φ76 | |

Weight | Kg | 685 | 850 | 1200 | 1650 | 2300 | 3100 | |

Dimensions | Length | mm | 1100 | 1200 | 1450 | 1700 | 1750 | 1800 |

Width | mm | 950 | 1000 | 1150 | 13500 | 1450 | 1500 | |

Height | mm | 1450 | 1500 | 1700 | 2000 | 2000 | 2100 | |